.png)

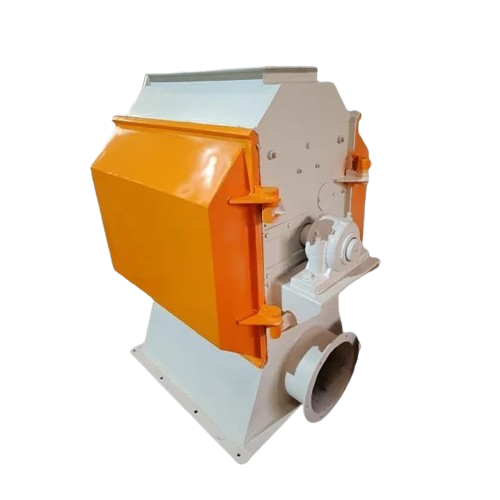

The Pellet Cooler is used for cooling hot feed pellets from 800 C to ambient temperature.

It consists of an intake box made from Stainless Steel plates with the top cover of bolted construction. It contains SS wedge plate for pellet distribution on both sides of the cooler column with SS flap supported on bearings.

On one end there is provision for a mercury switch and on the other end a suitable balancing weight is provided for automatic operation of the discharger.

When the column becomes full, the flap gets lifted and the mercury switch operates the auxiliary contact of the starter for the discharger motor and the discharger.

Cooling columns are on either side with central duct for conveying hot air. SS wire mesh separates pellets from air.

Set of louvers (flaps) regulate flow of cold air inside the cooler. The pellets while falling operate inside portion of the flaps and cold air is passed through stock of pellets. Pellet discharger has an arrangement for pellet collection and flow adjusting through a mechanism. The discharging mechanism with Spring Steel strips vibrates by means of eccentric drive with pulleys fitted with weights.

Enquiry Now

.png)

.png)

.png)

.png)

1.png)

2.png)

3.png)