.png)

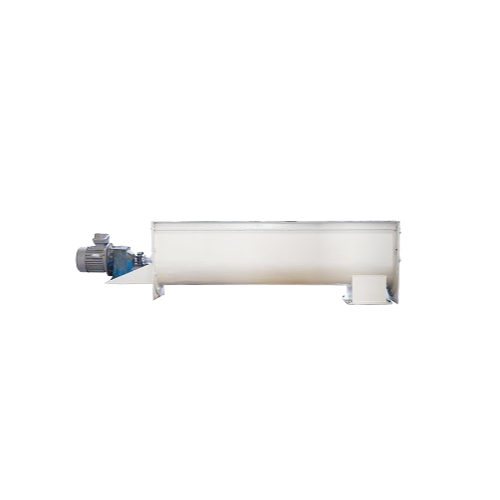

When the propeller starts to rotate, the small feed hopper impeller chamber is forcibly sent into the conveying pipeline, and then lifted by the propeller to the top of the mixing barrel, at which time the material will be evenly scattered in the mixing barrel.

The material rises and falls in the mixing tank and rotates left and right continuously to form a mixing process, thereby achieving a uniform mixing effect.

Enquiry Now

.png)

.png)

.png)

.png)

1.png)

2.png)

3.png)